PRODUCTS

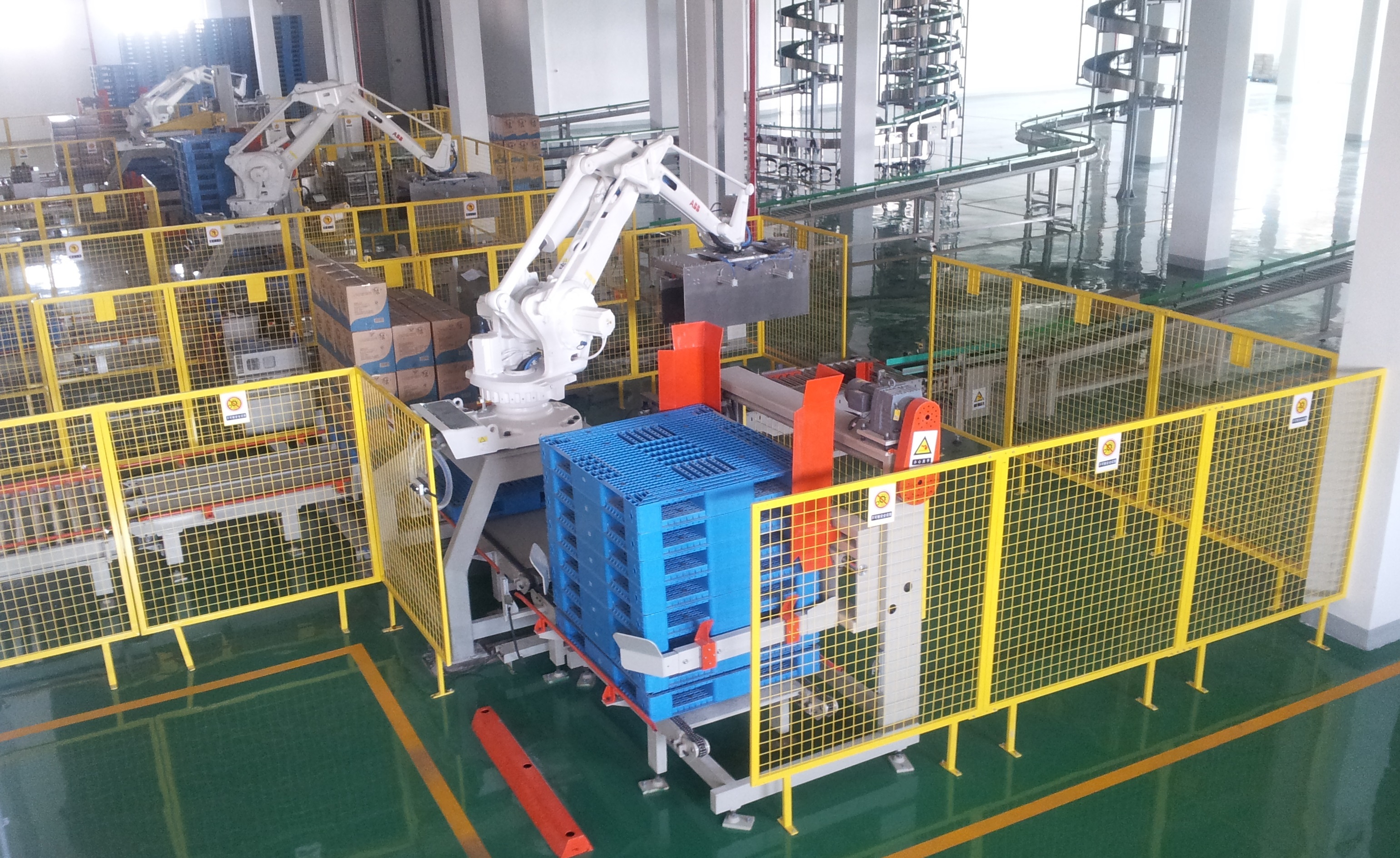

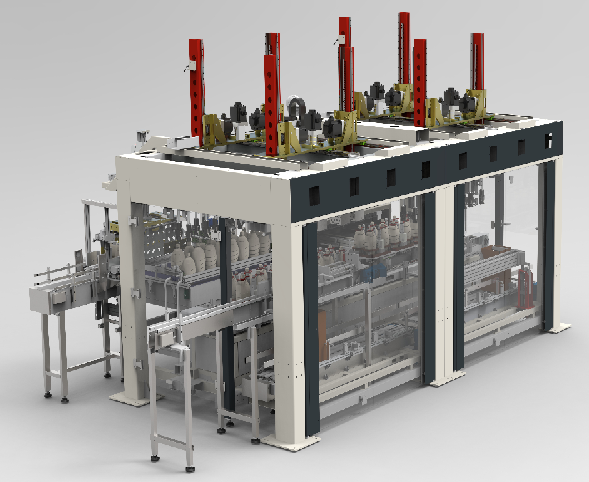

Clamp-type Automatic Case Packer

Category:

Products Category

Introduction

-

Technical Parameter:

Case packers can be classified according to the number of synchronous packing boxes at a time into three-station, four-station, five-station, six-station and eight-station case packers. The performance parameters are as follows. There are multiple models available for each type of station case packer to meet the packing requirements of different production capacities for products of different specifications.

Model GT-JZ320 GT-JZ321 GT-JZ322 GT-JZ340 Name Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Applicable product specifications 0.4L/0.7L/0.9L, 1.8L, 2.5L, 5L PET

10L PET 0.4L/0.7L/0.9L/1.8L/2.5L PET

0.4L/0.7L/0.9L PET

Capacity 0.4L :5000 BPH (20 bottles/carton)

0.7L/0.9L :5000 BPH (15 bottles/carton)

1.8L/2.5L:5000 BPH (6 bottles/carton)

5L:3000 BPH (4 bottles/carton)

1800 BPH (2 bottles/carton) 0.4L:5000 BPH(20 bottles/carton)

0.7L/0.9L:5000 BPH (15 bottles/carton)

1.8L/2.5L:6000 BPH (6 bottles/carton)

0.4L:6000 BPH(20 bottles/carton)

0.7L/0.9L:6000 BPH (15 bottles/carton)

Dimension 3000mm × 2060mm × 2230mm 3000mm × 2300mm × 2230mm Weight 1500kg Material Packing machine body sheet metal material: stainless steel; Roller material: stainless steel Conveying surface height 1080mm Air pressure 6-7 Bar Air consumption 220NL/min Power supply 380V,50Hz,4.7kW (three-phase, five-wire) 380V,50Hz,5.4kW (three-phase five-wire) Model GT-JZ411 GT-JZ420 GT-JZ431 Name Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Applicable product specifications 5L (four stations) compatible with

10L (three stations)

20L palletizing compatible 20L packing 20L (four stations) compatible with

10L (three stations)

Capacity 5L:4300 BPH (4 bottles/carton)

10L:1800 BPH (2 bottles/carton)

20L:1200 BPH (1 bottle/carton) 10L:1800 BPH (2 bottles/cartin)

20L:1200 BPH(1 bottle/carton)

Dimension 3000mm × 2060mm × 2230mm 2570mm × 1750mm × 2320mm 4180mm × 2410mm × 2320mm Weight 1500kg 1800kg 1600kg Conveying surface height 1080mm Number of bottle columns Single row Material Packing machine body sheet metal material: stainless steel; Roller material: stainless steel Air pressure 6-7Bar Air consumption 220NL/min 250NL/min 250NL/min Power supply 380V,50Hz,4.7kW (three-phase, five-wire) 380V,50Hz,8.9kW (three-phase, five-wire) 380V,50Hz,5.9kW (three-phase, five-wire) Model GT-JZ520 GT-JZ521 Name Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Applicable product specifications 5L (five stations), 10L (four stations) 5L Compatible 5L Bundle Capacity 5L:6000 BPH (4 bottles/carton)

10L single row: 2400 BPH (2 bottles/carton)

5L:6000 BPH (4 bottles/carton)

5L bundle: 4800 BPH (4 bottles/carton)

Dimension 3610mm × 3590mm × 2230mm 3610mm × 3940mm × 2230mm Weight 2500kg Material Packing machine body sheet metal material: stainless steel; Roller material: stainless steel Conveying surface height 1080mm Air pressure 6-7Bar Air consumption 250NL/min Power supply 380V,50Hz,6.6kW (three-phase, five-wire) Model GT-JZ610 GT-JZ612 GT-JZ622 Equipment Name Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Clamp-type Automatic Case Packer Applicable product specifications 10L (five stations) compatible with 5L (six stations) 5L (six stations) compatible with 10L (five stations) 0.9L, 1.8L, 2.5L Capacity 5L (single row):5700 BPH (4 bottles/carton)

10L (single row):3000 BPH (2 bottles/carton)

5L (double row):6700 BPH (4 bottles/carton)

10L (single row):3000 BPH (2 bottles/carton)

0.9L:10000 BPH (15 bottles/carton)

1.8L/2.5L:10000 BPH (6 bottles/carton)

Dimension 4790mm × 3370mm × 2300mm 4790mm × 3370mm × 2300mm 5010mm × 3150mm × 2300mm Weight 2900kg Material Packing machine body sheet metal material: stainless steel; Roller material: stainless steel Conveying surface height 1080mm Air pressure 6-7Bar Air consumption 255NL/min 250NL/min Power supply 380V,50Hz,9.4kW (three-phase five-wire) Model GT-JZ810 Equipment Name Clamp-type Automatic Case Packer Applicable product specifications 10L Capacity 10L:4000 BPH (2 bottles/carton) Dimension 3520mm × 3700mm × 2230mm Weight 2650kg Material Packing machine body sheet metal material: stainless steel; Roller material: stainless steel Conveying surface height 1080mm Air pressure 6-7Bar Air consumption 280NL/min Power supply 380V,50Hz,9.4kW (three-phase five-wire) Features:

1. Independent intellectual property rights; Advanced technology and a number of national patents.

Products Patent Name Patent Certificate Number automatic cartoning machine Automatic packing machine fixed collection platform device 2778326 Fixture interchange device for automatic packing machine 2775328 Automatic packing machine whole row bottle pushing mechanism 2749020 Automatic packing machine without counterweight soft connection mechanism 2748817 pneumatic gripper mechanism 2764730 Plate-type bottle clamping mechanism 2750580 Bottle body pneumatic gripping clamp 4841072 2. Coordinated action, stable operation, simple operation, automatic equipment without manual intervention.

3. The chuck adopts a self-locking design to ensure that the bottle does not fall when the clamp is in place. Improve the stability of packing.

4. The aluminum alloy structure fixture is modular, light and dexterous, and the drawer-type fixture replacement structure ensures that the fixture is replaced quickly and quickly, and there is no need to adjust the bottle.

5. The most stable packing method: using imported Germany SEW servo motor with geared motor for precise positioning, clamping and packing.

6. Patented technology: the application of automatic packing machine without counterweight soft connection mechanism, with the use of high-quality imported servo motor, to increase the accuracy and stability of packing and improve the packing speed, is the fastest and most stable high-speed packing machine.

7. Imported PLC + touch screen control, automatic monitoring and alarm prompts and operation data collection in the whole process of operation.

8. A number of automatic safety protection functions, production is safer, packaging is more efficient.

9. Faster adjustment of the module to ensure the convenience and reliability of adjusting specifications.

Keyword:

Aluminum Alloy Photovoltaic Stents

Previous:

Related Products

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容