PRODUCTS

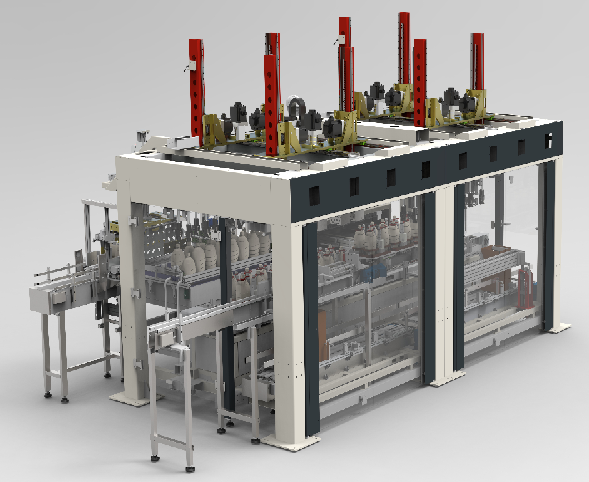

Bundled Ring Pressing Integrated Packer

Category:

Products Category

Introduction

-

Operating Principle:

1. Small bottles are transported from the small specification bottle feeding line to the designated position, where the mechanical gripper grabs the small oil bottle and adjusts its position, placing it in the parallel cross dual-track A or B tooling.

2. Large oil bottles are sent to the designated position by the large specification bottle feeding line, where the mechanical gripper grabs the large oil bottle and adjusts its position, placing it in the parallel cross dual-track A or B tooling.

3. The ring placing station is completed manually, where the ring is placed at the designated position, and the bottom ring receiving device transfers the ring to the ring taking position.

4. The translation device moves the tooling containing the large and small oil bottles to the ring pressing station, where the ring pressing device takes out the bundled lifting ring and simultaneously presses it into the mouths of the large and small bottles.

5. The box feeding station delivers 4 cartons to the position directly below the box pressing frame at each cycle.

6. The boxing fixture simultaneously grabs the large and small oil bottles with the pressed bundled lifting rings, adjusts their positions, and places them into the cartons, thus completing the entire bundling, ring pressing, and boxing process in a cyclic manner.Technical Innovation:

1. The entire machine is designed with a self-developed integrated full-stack design concept, ensuring precise positioning and transportation of auxiliary materials, facilitating the insertion of lifting rings.

2. The large bottle, small bottle, and boxing fixtures adopt a flexible self-adaptive adjustment method, allowing for one-click switching.

3. The parallel cross dual-track operates independently, seamlessly connecting the actions of each station.

4. The entire machine's fixture has a full-link dynamic detection and alarm function for missing bottles and dropped bottles.

5. While achieving bundling and boxing, the efficiency of large bottle boxing is improved by 30% compared to standard products.

6. The entire machine has a total of 25 axes of servo linkage control, ensuring stability and efficiency.Features:

1. Large bottles use a dual-row bottle feeding line, while small bottles are conveyed in a multi-path orderly stacking manner, ensuring high efficiency and speed.

2. The bottle blocking device and bottle feeding counting adjustment device both use a handle knob for adjustment, allowing for adjustments in the X and Y directions, facilitating quick production specification switching for operators.

3. Imported high-quality electrical and pneumatic components, including German SEW reduction motors and servo motors, ensure smooth and reliable operation, with a machine lifespan exceeding 15 years.

4. Imported PLC + touch screen control, with automatic monitoring and prompts during operation.

5. Multiple automatic safety protection functions, making production safer and packaging more efficient.Technical Parameters:

Model

GT-KYZ410

Equipment Name

Bundled Ring Pressing Integrated Packer

Applicable Products

Compliant with Bundling List

Capacity

25 cartons/minute

Material

High-quality carbon steel with spray coating, tempered glass protective door

Height of Bottle Feeding Conveyor

Large bottle 1200mm, small bottle 1300mm

Height of Inbound and Outbound Conveyor

500mm~570mm

Air Pressure

0.6Mpa Air Consumption

280NL/min

Power Supply

380V, 50Hz, 59 kW (three-phase five-wire system)

Weight 13500kg Dimensions (L)10200mm × (W)4910mm × (H)3900mm

Keyword:

Aluminum Alloy Photovoltaic Stents

Previous:

Related Products

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

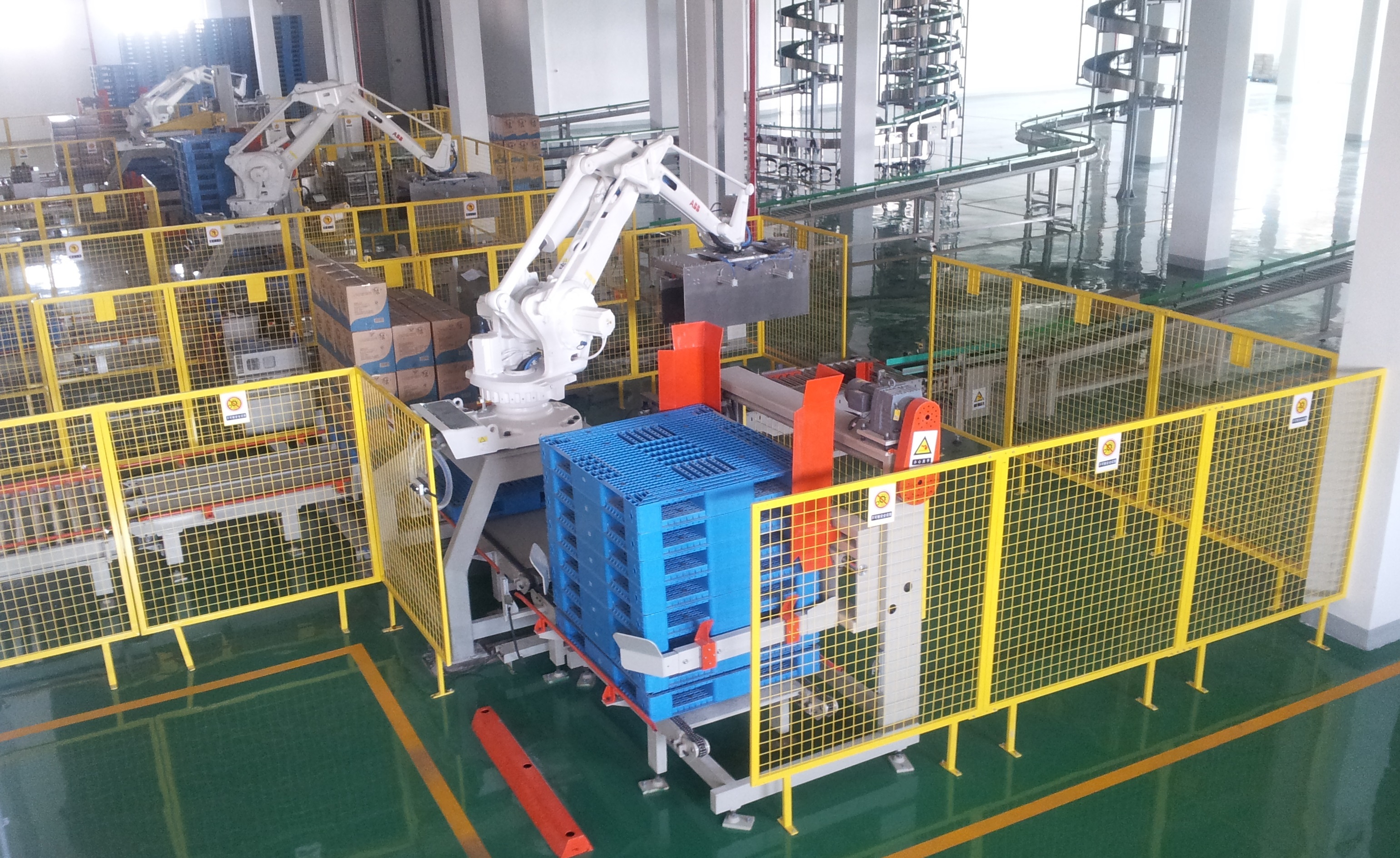

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容