PRODUCTS

Delta Robotic Handle Applicator

Category:

Products Category

Introduction

-

1. Background Technology of Handle Applicator:

With the continuous economic development and societal progress, the consumption of beverages, food, daily chemicals, and other products has been steadily increasing, leading to a growing diversity in packaging formats. Delta robots have become widely utilized in the daily chemical industry. However, in the oil industry, in the past few years, a portion of the 5L/10L/20L handle applicator were handled semi-automatically through manual labor, while others utilized centrifugal trays or vibrating trays. Manual handle applicator resulted in inefficiency and safety concerns, whereas centrifugal and vibrating trays exhibited high failure rates, significant noise levels, high energy consumption, and were prone to debris generation. Their compatibility was limited, especially for incoming materials above 10L. Hence, Delta robotic handle applicator has emerged as a new trend and a technological advancement.

2. Application of Delta Robotic Handle Applicator :

The development of handle applicator machines for intermediate packaging in China has been tailored to specific on-site spatial requirements, addressing the previous issue of manual emi- automatic ring installation commonly used in intermediate packaging. Delta robots dominate 70% of the daily chemical/pharmaceutical industries, while currently, through technological extensions, they have begun to be widely adopted in the grease industry.

3. Capacity of Delta Robotic Handle Applicator:

➢ Single Picking Head: 2000 BPH (5L), 800 BPH (20L)

➢ Double Picking Heads: 4000 BPH (5L), 1600 BPH (20L)

➢ Triple Picking Heads: 6000 BPH(5L)Safety Measures:

Equipped with safety doors for instant machine halt upon door opening. The operational area of the spider-hand robot is shielded comprehensively, with all transmission components safeguarded.

Remote Intelligent System:

Employs remote monitoring for program execution and intelligent fault detection, empowering manufacturers to diagnose and resolve equipment malfunctions remotely. This maximizes operational reliability, enabling truly smart production.

Compliance with Food Safety Standards:

Includes ring supply organization and retrieval systems, enhanced with foreign object prevention tools like fan blowing and negative ion dust removal.These elements swiftly remove plastic particles and paper debris adhering to the hanging rings, mitigating the risk of foreign object contamination.

Vision Recognition System:

Utilizes advanced logic algorithms for swift and accurate identification of hanging ring status and position. Subsequently, the Delta robot swiftly grips and precisely fits the target rings onto bottles in the correct orientation. This completes the entire process of automatic feeding, identification, sorting, grabbing, and fitting of the hanging rings. Non-target hanging rings are conveyed back to the material hopper via the hanging ring recovery system for recycling, then looped back to the pre-sorting line for further processing.

Terminal Configuration of Ring Pressing:

Equipped with a leak ring visual detection alarm shutdown feature, along with audible and visual prompts.

Dustproof Covers:

Positioned above the ring pressing equipment and conveyor systems to prevent dust accumulation.

Alarm Notifications:

Utilizes pop-up alerts on the operation screen, supplemented by audible and visual cues for streamlined troubleshooting and rapid fault resolution.

Related Products

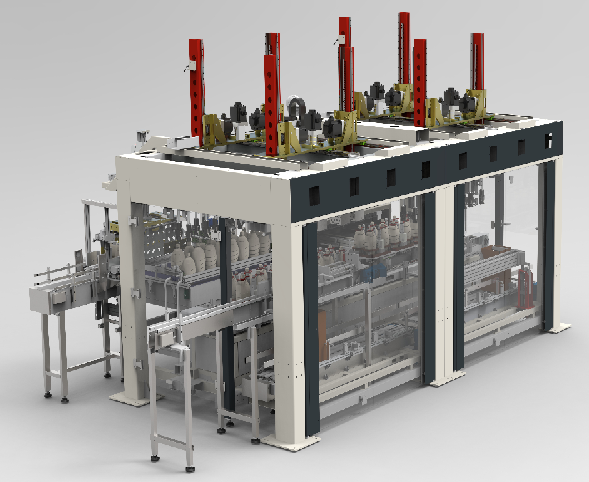

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

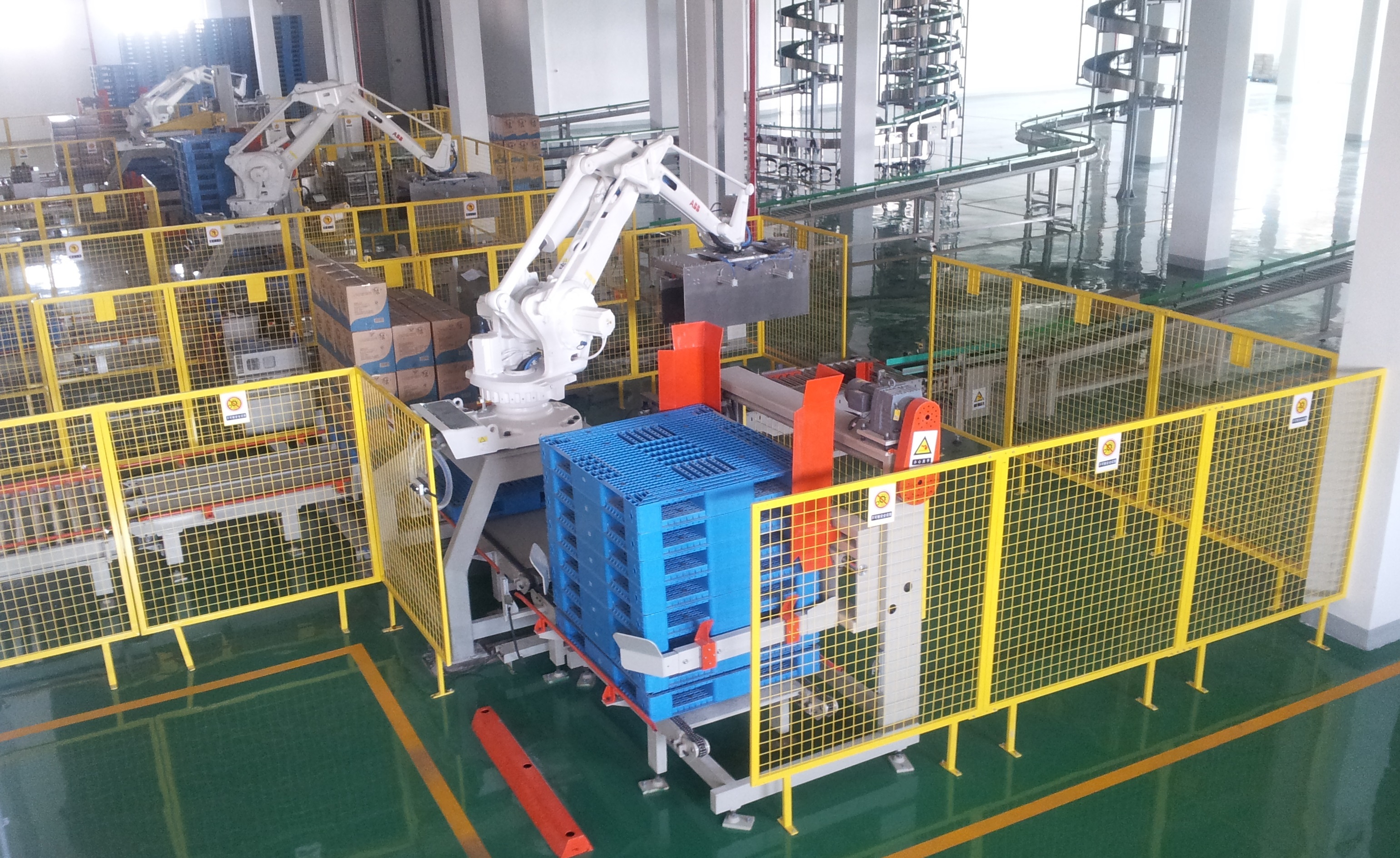

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容