PRODUCTS

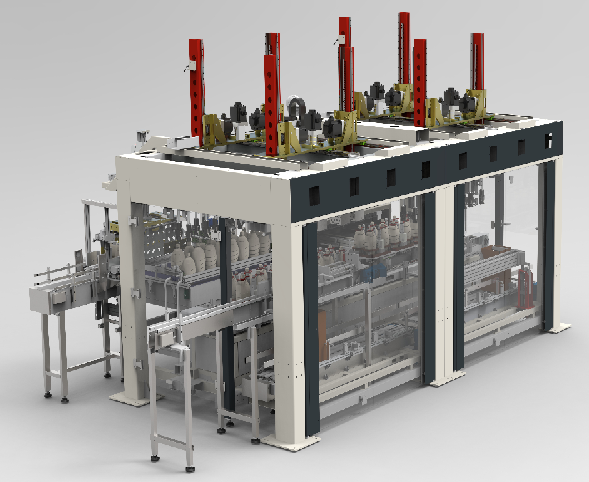

Linear Weighing Filling & Capping Machine

Category:

Products Category

Introduction

-

Filling Principle:

The container is transported to the filling machine without needing to be separated. The products are filled into the container by weight reduction method, with an electronic scale detecting the filling weight in real-time. Once the set value is reached, a signal is sent to close the filling valve, stopping the filling process. The electronic scale then checks the container again (container + contents) to ensure the accuracy of the filling. The filled containers are then transported to the capping machine for sealing. This machine uses PLC + touch screen control, and the electronic weighing device is from the German company HBM. Each electronic scale can be set to individual values to ensure the accuracy of the filling.

Technical Parameters:

Item Technical Parameters Capacity 2500BPH/5L (Filling Valve/Weighing Unit: 16 units)

1800BPH/5L (Filling Valve/Weighing Unit: 12 units)

1000BPH/20L (Filling Valve/Weighing Unit: 10 units)

800BPH/20L (Filling Valve/Weighing Unit: 8 units)

Filling Product Edible Oil Production efficiency of the whole machine 96% Average Accuracy 3σ≤±2g Total Power of Equipment 2KW, AC380C/50HZ Control Power Supply 24V DC Compressed Air Pressure: 0.4~0.7MPa, Air Consumption: 50L/min Conveying Height 800±50mm (can be customized according to customer requirements) Dimensions L3000Xw2000xH3400 Weight 3000kg Equipment Material:

1. Overall machine material:

- Corrosive parts use stainless steel components made of SUS304.

- Wear parts such as guide plates use high-density polyethylene material that is wear-resistant and corrosion-resistant.

- The equipment frame is designed entirely in stainless steel, made of welded SUS304 stainless steel pipes, and integrated with SUS304 stainless steel plates.

- Safety doors use tempered safety glass; the turntable covering material is SUS 304 stainless steel.

- The equipment electrical box and control box require SUS304 stainless steel material, with certain sealing performance to be waterproof and dustproof.2. All components are made of stainless steel (with parts in contact with filling materials using 304) or equally durable and corrosion-resistant materials, while others (frame and base) may be painted carbon steel with a layer of stainless steel sheet on the surface or food-grade plastic materials.

3. The sealing ring inside the filling valve is made of food-grade materials, using food-grade, oil-resistant, and wear-resistant materials.

4. The pneumatic components of the filling machine are made of stainless steel or plastic to avoid corrosion from environmental influences, eliminating the need for pneumatic components to lift bottles.

Advantages of the Weighing Filling Unit:

- The electronic weighing system uses imported high-quality brand products (HBM) with high-precision sensors to ensure filling accuracy.- High filling accuracy.

- High hygiene level, as the filling valve nozzle does not contact the bottle during filling.

- Uses an advanced filling system that is simple and easy to use.

- Few moving parts in the system, reliable operation, and almost zero maintenance.

- Monitors each container, ensuring high product quality.

Keyword:

Aluminum Alloy Photovoltaic Stents

Next:

Related Products

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

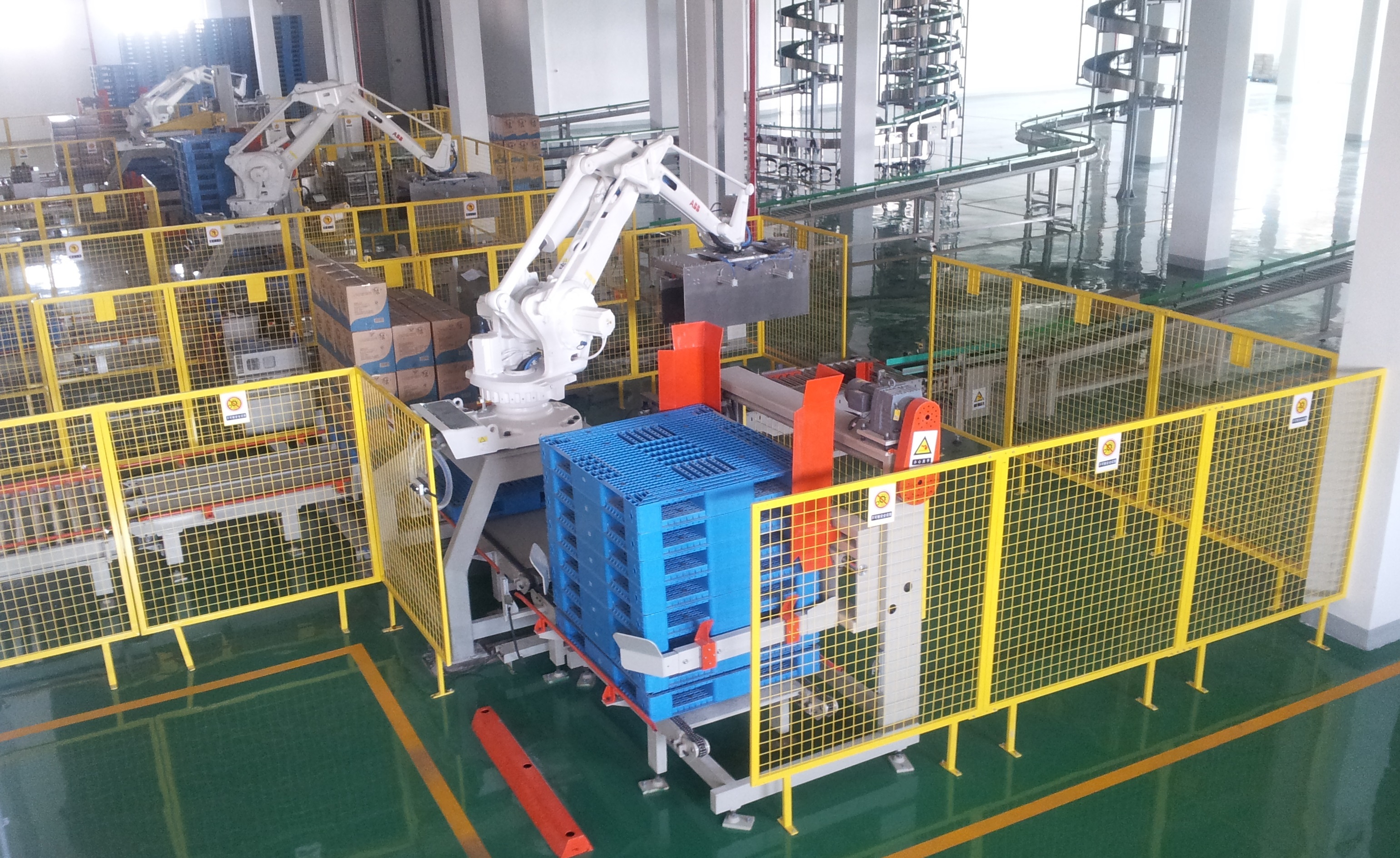

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容