PRODUCTS

Rotary Weighing Filling & Capping Machine

Category:

Products Category

Introduction

-

Products Overview

This machine is used in the precision filling production of high value-added liquids such as large-capacity PET bottles, HDPE bottles, PE bottles and glass bottles, and the filling machine product series adopts electronic weighing filling technology, the filling measurement is accurate, and the average filling accuracy of the product can reach ±2 grams (5L product σ value). This product series has complete specifications, mature technology, and stable and efficient equipment operation.

This machine series is compatible with large and small volume filling, and the product series can be widely used in food, condiments, industrial lubricants and chemical products, such as honey, edible oil, car lubricating oil, brake fluid, personal advanced hygiene products filling production.

For the bottling production of materials with different properties, different uses and different hygienic requirements, we have corresponding personalized technical solutions and configuration schemes.

The filling and capping combination machine specially used in edible oil filling is in line with the use characteristics and hygienic requirements of edible oil filling production.

Technical parameters:

Items Technical parameters Equipment Model HT-RW/S-20/6 Capacity 4500BPH/5L Filling products edible oil Production efficiency of the whole machine 96% Accuracy average 2σ≤ 2g Filling valve/weighing unit 20 Caping head 6 pcs Total power of equipment 6KW,AC380C/50HZ Control power supply 24V DC Compressed air Pressure: 0.4~0.7MPa, air consumption: 600L/min Conveying height 1000±50mm Dimension L3400Xw2500xH3500 Weight 6000kg Equipment material:

1. Material of the whole machine

- Metal parts made of stainless steel and prone to corrosion are all made of SUS304 material.

- Wear resistant and corrosion-resistant high-density polyethylene materials are used for vulnerable parts such as star wheels and guide plates.

- The equipment bracket is made of high-quality welded steel and has undergone professional anti-corrosion and rust prevention treatment on the surface; The chassis is welded with high-quality steel plates, and the upper surface and periphery are integrated with SUS304 stainless steel plate layers.

- The safety door is made of transparent plastic material or tempered safety glass; The wrapping material of the turntable is SUS 304 stainless steel.

- The equipment electrical box and control box require SUS304 stainless steel material with certain sealing performance, which can be waterproof and dustproof.

2. All components are made of stainless steel (with 304 used for the parts in contact with the filling material) or equivalent corrosion-resistant and durable materials, while the rest are made of (frame and machine base or painted carbon steel, covered with a layer of stainless steel plate on the surface) or food grade plastic materials.

3. The sealing ring inside the filling valve is made of oil resistant and wear-resistant materials.

4. The pneumatic components of the filling machine are made of stainless steel or plastic material to avoid corrosion caused by environmental factors, and there is no need for pneumatic components to lift the bottle.

Lubrication system:

The whole machine is automatically and centrally lubricated, the operation cycle can be set, and the gear and gland machine guide rail can be automatically lubricated, without manual lubrication.

One-key operation system for CIP:

CIP double spray ball (no dead angle), using double spray nozzle, no dead angle all-round spray oil change on the filling cylinder and feed pipe, reduce the amount of oil used for oil change, shorten the oil change time, configure oil skimmer tank, pneumatic diaphragm pump, and set up a special one-key oil change program.Advantages of gravimetric filling units:

- The electronic weighing system adopts imported high-quality famous brand products (HBM) high-precision sensors to ensure the filling accuracy.

- High filling accuracy.

-High hygiene, the filling valve nozzle is not in contact with the bottle during filling.

- Adopt advanced filling system, simple and easy to use.

- The system has few moving parts with each other, operates reliably, and achieves almost zero maintenance.

- Each container is monitored, and the product quality is high.

Features of the bottle rejection system:

- Reject bottles with unqualified weights.

- Reject uncapped bottles.

Quick change for changeover parts:

- The parts that are changed each time are quick to change and do not need to be repositioned.

- Start the device at maximum speed after changeover.

Keyword:

Aluminum Alloy Photovoltaic Stents

Previous:

Related Products

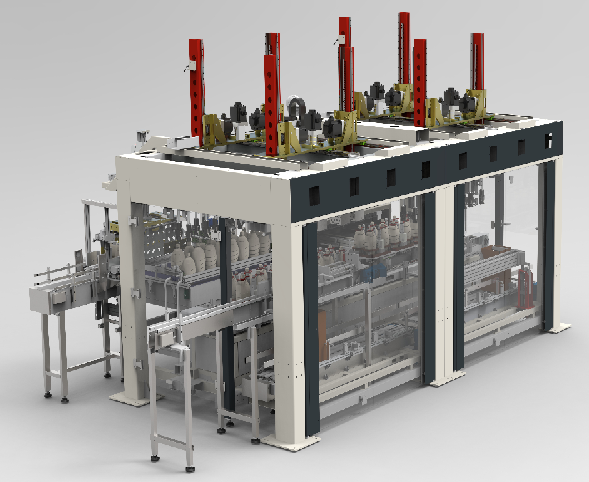

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

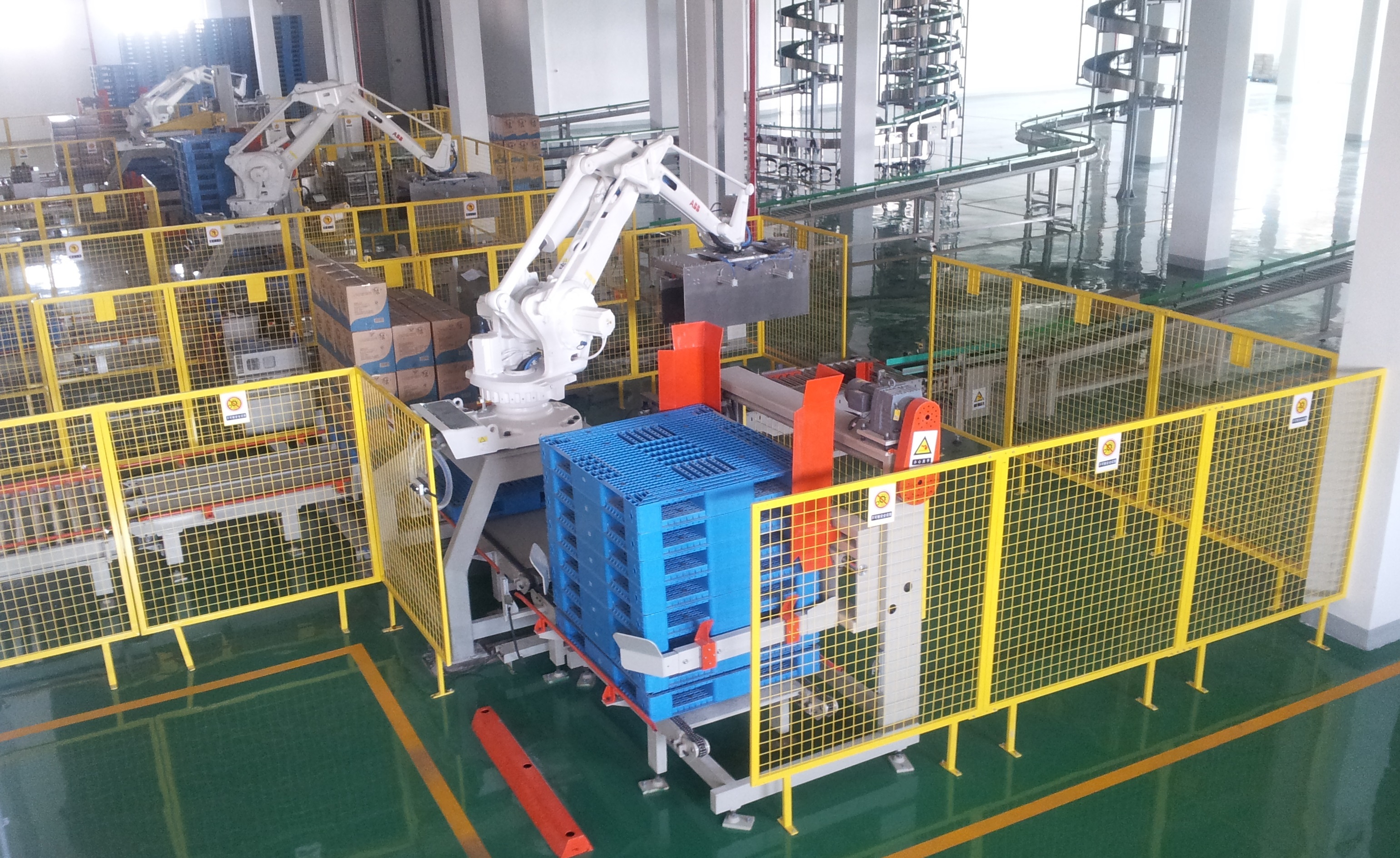

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容