PRODUCTS

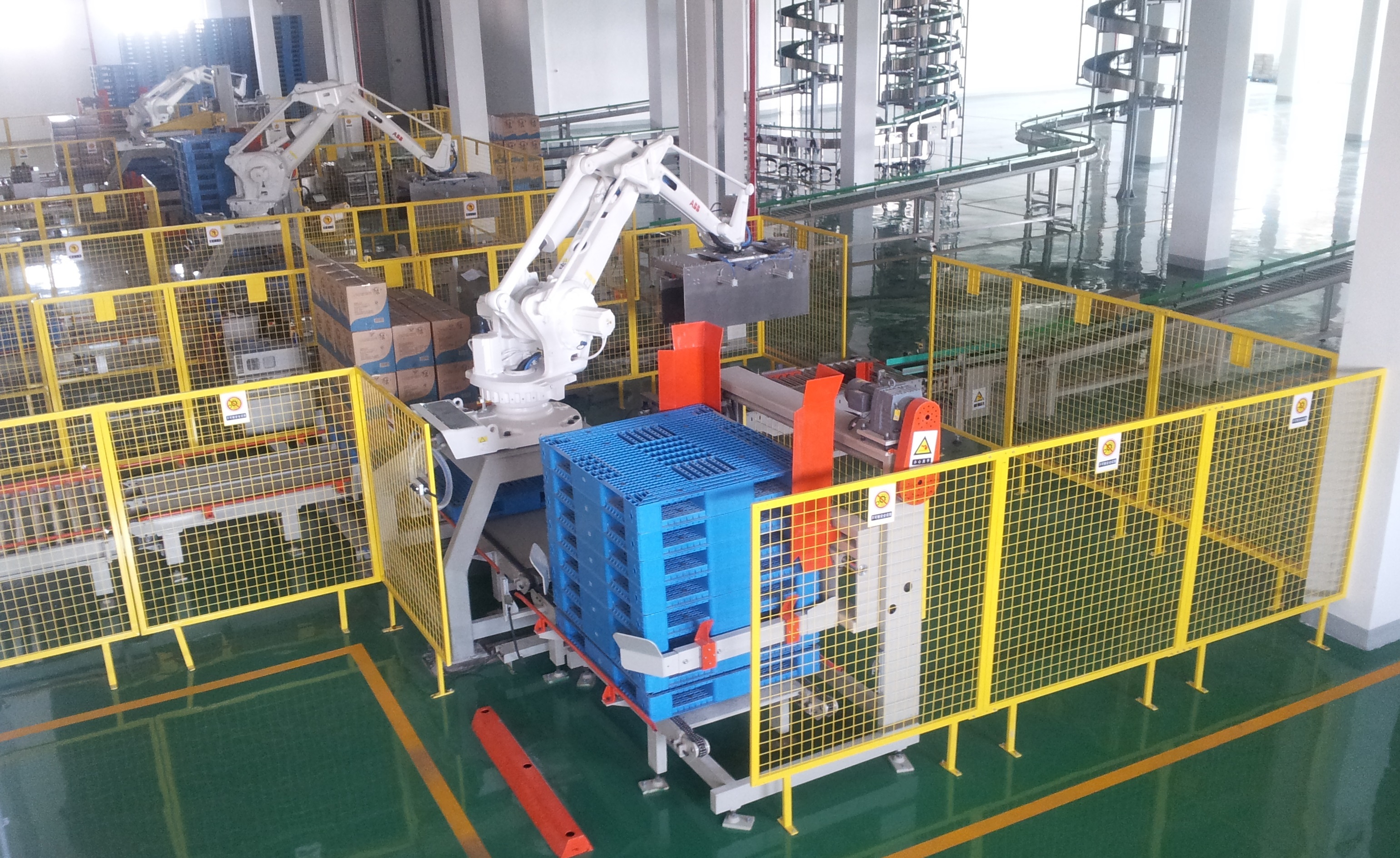

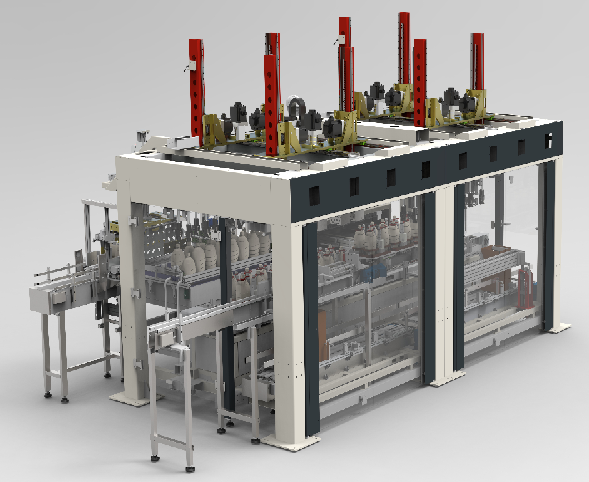

Robot Palletizing System

Category:

Products Category

Introduction

-

Features:

1. The powerful computing function of the robot, high-precision operation, and the repeated positioning accuracy reaches 0.1mm.

2. The control software is designed by experts, which realizes a high degree of automation and intelligence of the system.

3. Servo motors, programmable controllers, and frequency conversion speed controllers adopt world-class products to ensure the reliability and long life of system hardware.

4. Sturdy and durable, up to IP67 protection level, it can run smoothly in the harshest production environment.

5. Flexible layout, can be set in a narrow space, can also be stacked three lines at the same time.

6. The stacking method adjustment is convenient and simple, and the stacking of various specifications and methods can be completed without replacing parts, which can be operated on the touch screen.

7. Perfect safety interlock mechanism, which can provide protection for equipment and operators.

8. Including inlet and outlet grating, the pallet supplier adopts cylinder lifting type (with heightened plate silo), and the guardrail is thickened.System Control:

1. The whole system, palletizing and confluence, packing, forming a communication network. The internal and peripheral equipment of the system can be exchanged through Ethernet, which is convenient for daily maintenance and repair, and the system is stable and reliable. It is connected to the computer system in the central control room of the production line to realize data sharing and management.

2. The palletizing part adopts PLC as the main station, and the robot as the auxiliary station, which communicates with the robot through the PROFIBUS fieldbus.

3. The PLC program and the robot program are modular design, which is easy to modify, ensure the reliability of the program, and facilitate the upgrade, and the performance of the system must be reliable.

4. All motor control adopts intelligent control mode, the motor will automatically start in advance when there is material passing, and the motor will automatically stop when no material passes.

5. Adopt a combined electric cabinet, made of carbon steel sprayed plastic, with a 200mm high separation base, the cabinet protection level reaches IP54, and the cabinet is equipped with a cooling fan, fluorescent lamp and trunking.

6. The strong current and weak current inside the electric cabinet are separately wired, all wiring are marked with the wire number, the wire end is crimped with a terminal, the contact of each element is allowed to connect two wires at most, all wires in the cabinet are not allowed to have joints, and the protective grounding wire (yellow and green wire) is not less than 2.5mm2.

7. The protective grounding terminal is separated from the protective zero terminal, and no less than 10% of the terminal position is reserved in the cabinet.

8. The whole line is laid with hot-dip galvanized bridges and brackets, and the power line and signal line are routed separately; The outer part of the cable is made of bellows sheath made of PA material, which is reasonably arranged, beautiful and rodent-proof.

9. The touch screen of the electrical control box is installed to startresetstopemergency stop switch, and all outputs are stopped after the emergency stop button is pressed, and the detection device is not affected.

10. The power supply of the touch screen is provided by the PLC power supply modularly, and the internal position of the equipment is adjusted, and there are different control interfaces.

11. The equipment fault alarm information is recorded in detail, which is convenient for timely handling of faults, and the fault history is saved for future reference. All control points have alarm feedback signals to monitor the current working status of all motors and sensors in real time.

12. The safety protection function of the equipment must be complete, and the safety of man and machine must be ensured through various sensors, safety door lock switches, emergency stop switches, etc.

13. The total power supply is set to 380V for three-phase five-wire system, and the PLC is powered by single-phase 220V power supply, and the 24V DC power supply is provided for the power supply of control circuits and detection components. All control circuits are powered by DC 24V and AC 220V power supplies.

14. The reciprocating cable of the equipment is protected by a special mobile cable and CABE CHAIN.

Related Products

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容