PRODUCTS

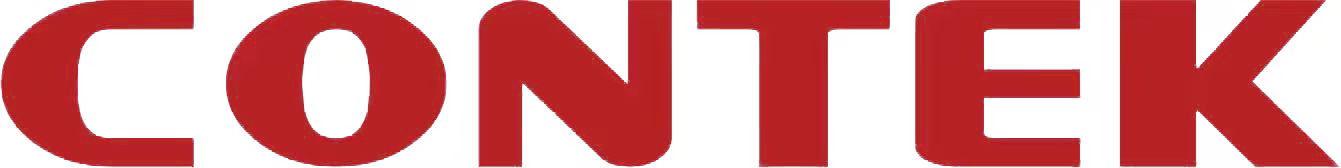

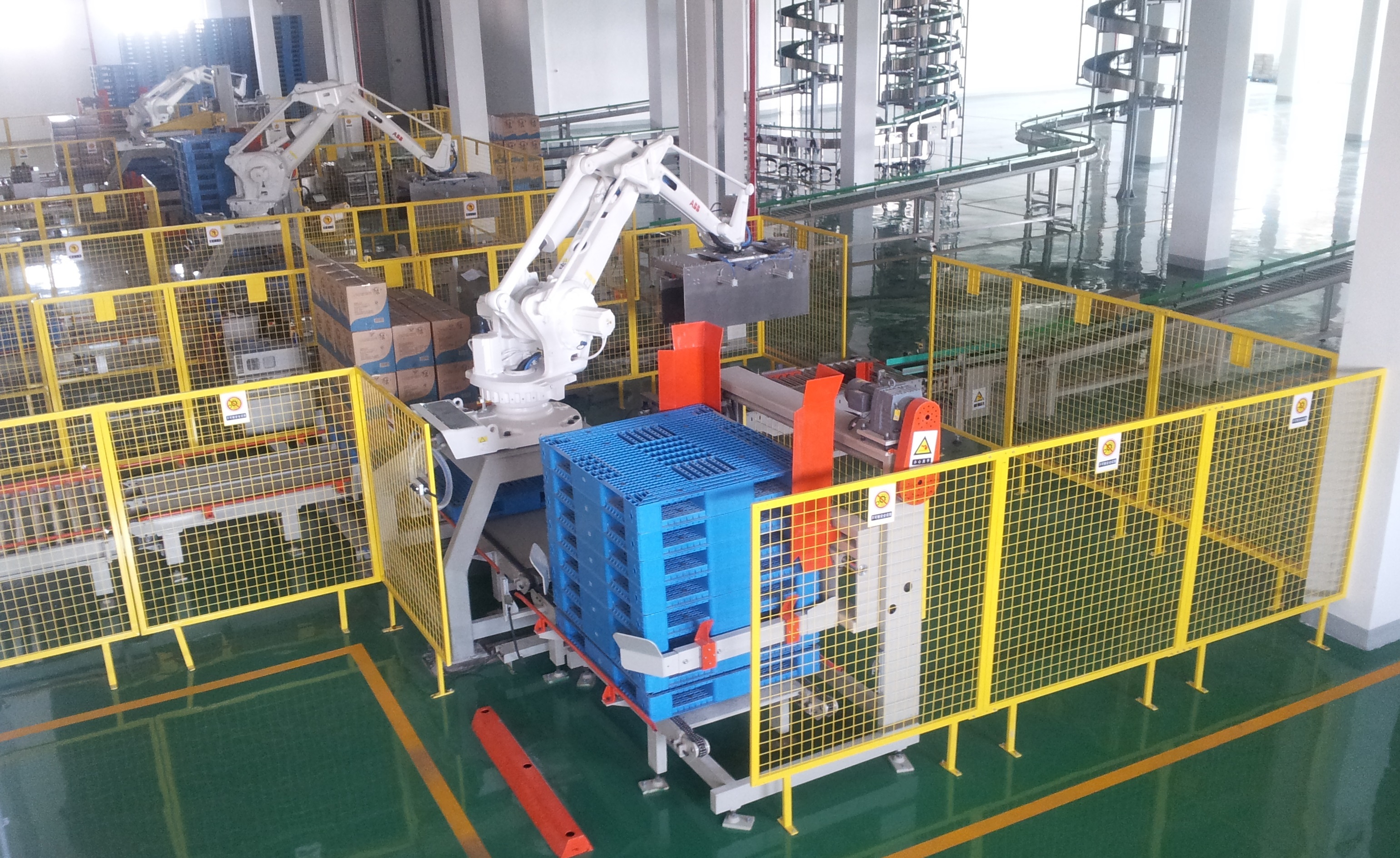

Grab Type Palletizer

Category:

Products Category

Introduction

-

Features:

1. Human-machine interface operation is used to realize man-machine dialogue, which can display the production speed, fault cause and location, and has a high degree of automation. PLC programmable can be used to control the sorting of cartons, the number of stacking layers, the supply and discharge of pallets.

2. The equipment guardrail is equipped with a photoelectric induction device when the door is opened, and the machine stops working to protect the operator.

3. The stacking method is easy and simple to adjust, and can be operated on the touch screen.

4. Stacking is stable and efficient, which can greatly save manpower.

5. Low noise, in line with China's international standard, noise is below 75DB.

6. Several stacking methods can be completed without replacing the stacking parts.

7. Low-level palletizing type, international advanced design concept, more advanced and reasonable structure, lighter and more stable action, and less power consumption.

8. FESTO cylinder, reliable quality and performance, can meet high intensity, long time work

9. The palletizing method can be carried out on the man-machine interface, and the adjustment is simple. A variety of palletizing methods can be completed without changing parts.

10. The electrical components are all European German brands, with stable and efficient performance and great manpower saving.

11. Hygienic requirements: the use of oil-free pneumatic components, 60% of the moving parts are made of life-long lubrication of the humanized design, for the user to reduce a lot of costs.

Technical parameters:

Model GT-GM100 Capacity 3 beats/minute Operation mode Man-machine interface touch screen Conveying table height 1000MM Max load per layer 250KG Max load per pallet 1500KG Max stacking height 1800MM (other height, can be customized) Use max pallet size 1300*1100MM (other sizes, can be customized) Power supply AC,3 phase, 380V,6.5KW,50HZ Air consumption 64NL/min Dimension 3700mm × 1950mm × 3000mm (code box) Weight 2100KG

Keyword:

Aluminum Alloy Photovoltaic Stents

Previous:

Next:

Related Products

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容