PRODUCTS

Automatic Cap Feeder

Category:

Products Category

Introduction

-

Features:

1. It is used in conjunction with the capping machine, and is controlled by independent PLC, and the process of capping, buffer platform, conveying, feeding and other processes is automatically operated, which is safe and reliable.

2. Automatic covering, automatic control of the number of covers.

3. Food-grade PP conveyor belt, all stainless steel dust cover, all stainless steel frame, in line with food safety requirements.

4. The damage rate of the cap during the feeding process is less than 1/10,000.

5. The hopper outlet should be equipped with an anti-slip device to prevent the lid material from slipping and bumping after the material is stopped, and the internal material of the hopper and equipment is stainless steel.

6. All imported electrical components are used to ensure the accurate, stable and high-speed operation of the system.

7. The blanking channel is required to be made of stainless steel pipe with a diameter of 220mm (excluding the stainless steel pipe through the layer and the flange connected to the blanking outlet of the feeder).Technical Parameters:

Model GT-PGJL100 Name Automatic Cap Feeder Applicable occasions Various types of bottle cap feeding Applicable bottle cap 10.6g and 5.8g bottle caps Capacity 6000 BPH Dimension 1707mm × 1000mm × 1533mm Vertical height drop of bottle cap ≤ 30cm Damage rate of bottle cap ≤ 0.1 ‰ Power supply 380V,50Hz, 0.55kW (three-phase, five-wire) Noise <80 dB

Keyword:

Aluminum Alloy Photovoltaic Stents

Previous:

Related Products

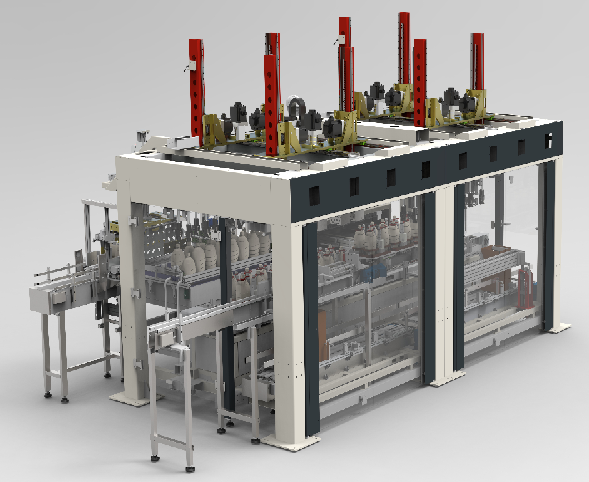

Bundled Ring Pressing Integrated Packer

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

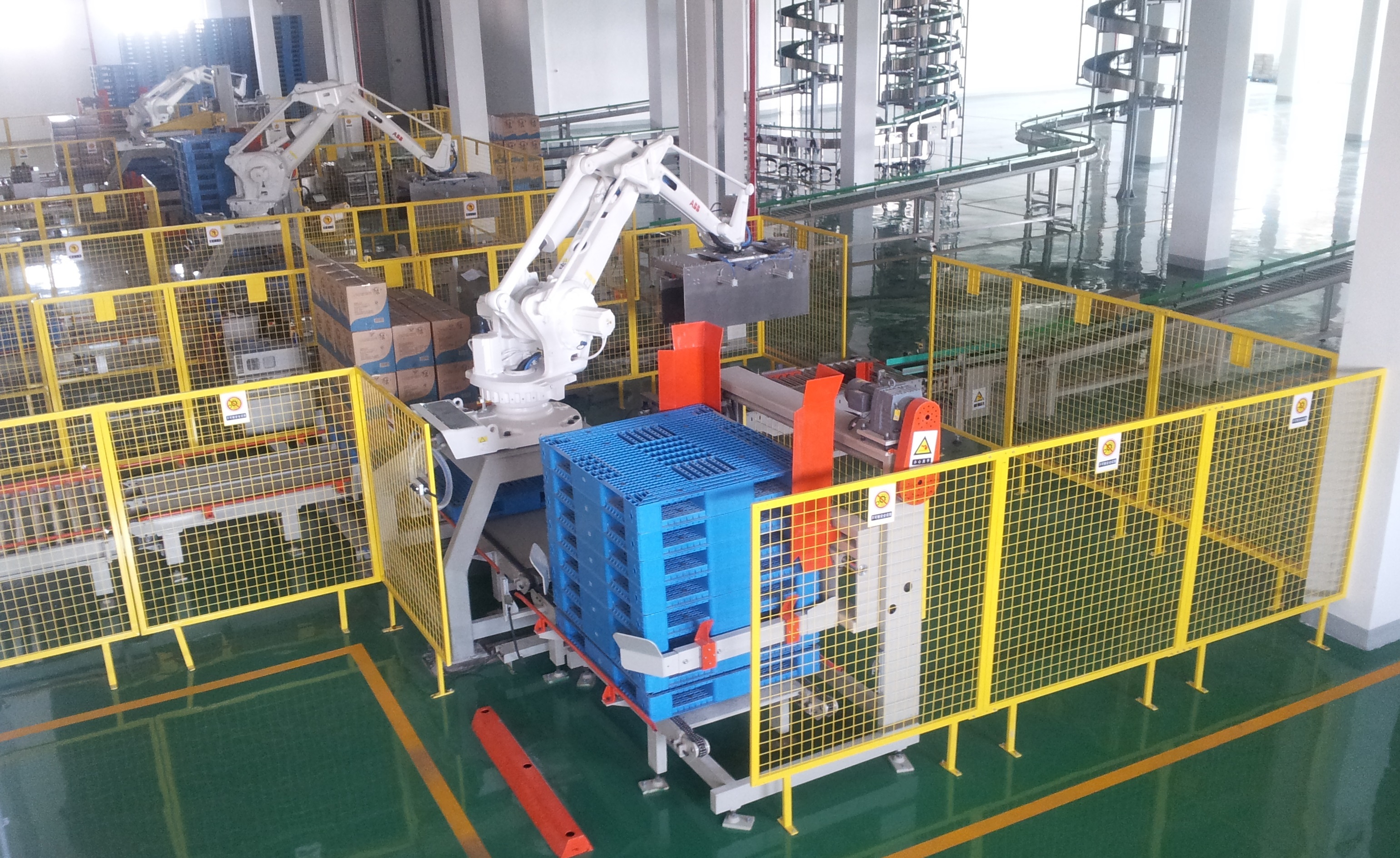

Automatic Depalletizing & Truck Loading System

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Automatic Strap Cutting & Carton Feeding Unit

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Auto-Buffer Horizontal Case Erector

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容