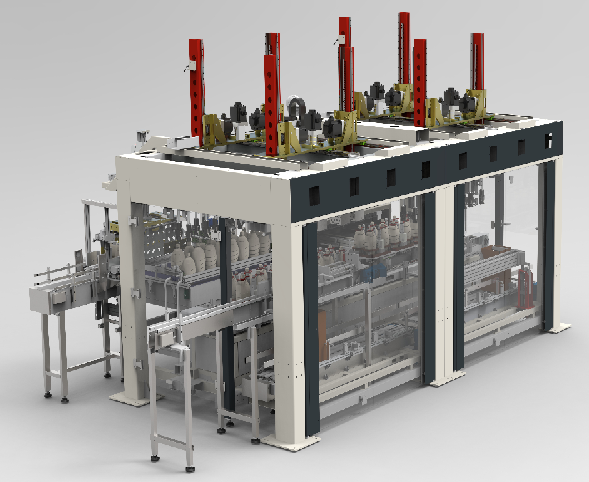

Bundled Ring Pressing Integrated Packer

The GT-KYZ410 Bundled Ring Pressing Integrated Packer is a specialized device that integrates bundling, ring pressing, and packing. This equipment can automatically grab bottles of various sizes, automatically take and press rings, and perform bundling and packing actions, effectively addressing the issues of cumbersome manual operations and low efficiency. The compact integrated structure of the equipment allows for multiple processes to work simultaneously, greatly enhancing production efficiency in packaging and thereby reducing production costs.

Automatic Depalletizing & Truck Loading System

The Automatic Depalletizing & Truck Loading System uses mechanized and automated methods to automatically unstack products in warehouses or on production lines, automatically sort and transport them into truck compartments and stack them neatly, realizing an automated and intelligent transportation and loading process. This effectively improves work efficiency and reduces the consumption of manpower and material resources.

Automatic Strap Cutting & Carton Feeding Unit

The GT-JSSH110 Automatic Strap Cutting and Carton Feeding Unit is a specialized device designed for automatic carton erector. This equipment performs automatic strap cutting and removal as well as automatic carton feeding, significantly improving work efficiency and reducing manual labor intensity.

Auto-Buffer Horizontal Case Erector

The buffering carton Erector is a product specifically developed for the characteristics of cartons in the edible oil industry. It is an automated packaging equipment that performs buffering feeding, single-carton separation, suction-based carton forming, bottom folding, sealing, and alignment correction on large quantities of cartons used in production lines. This equipment is one of the essential devices for achieving large-scale production in small packaging workshops.

ABP110 Buffering Conveyor Platform is a multi-lane parallel layout designed for conveying oil bottles of various specifications without guardrail adjustment. It integrates buffering, lane splitting, and storage functions, supporting both FIFO (First-In-First-Out) and LIFO (Last-In-First-Out) modes, offering flexible platform configuration.

High-speed Automatic Horizontal Carton Erector

The automatic horizontal carton erector is applicable to completing processes such as separating cartons one by one, sucking cartons, opening cartons, forming, folding the bottom, sealing the bottom and aligning in one go for a large number of cartons in continuous production. The speed of the high-speed carton erector is twice that of the standard carton erector.

Automatic Horizontal Carton Erector(Extended)

The automatic horizontal carton erector is applicable to completing processes such as separating cartons one by one, sucking cartons, opening cartons, forming, folding the bottom, sealing the bottom and aligning in one go for a large number of cartons in continuous production.

BIB Automatic Horizontal Carton Erector

The automatic horizontal carton erector is applicable to completing processes such as separating cartons one by one, sucking cartons, opening cartons, forming, folding the bottom, sealing the bottom and aligning in one go for a large number of cartons in continuous production.

Clamp-type Automatic Case Packer

The clamp-type case packer pushes the full bottles onto the packing platform via the bottle inlet conveyor line. Then, the grippers lift the oil bottles and move them horizontally to the packing position before moving downwards. Once in place, the grippers release to load the oil bottles into the empty cases.